Inside Liftgate Release Hardware

Cable Sheath Mounting Collar

Figure 1 |

Figure 2 |

Figure 3 |

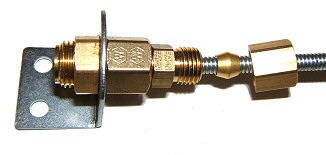

| The threaded collar on the

Dorman manual choke kit

(Part 55101) has the flange in front and threads in back (Figure 1). This makes for a nice looking installation, but it is difficult to

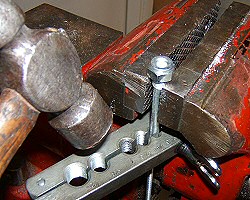

install the nut from behind in a tight space, and in this application the collar is not visible anyway. To hold the shaft so I could drive it out of the collar, I used the holder part of a brake line double-flaring tool kit (Figure 2). Common pliers might work but are more likely to slip and scratch; vise grips could crush the shaft. The top of the collar has an internal restriction, or throat, that must be drilled out to 1/4" (not pictured). After moving the nut flush with the end to avoid mashing the threads, I tapped the collar back onto the shaft (Figure 3). The finished assembly with collar reversed (Figure 4) makes installation much easier. |

Figure 4 |

Cable-End Barrel Stop

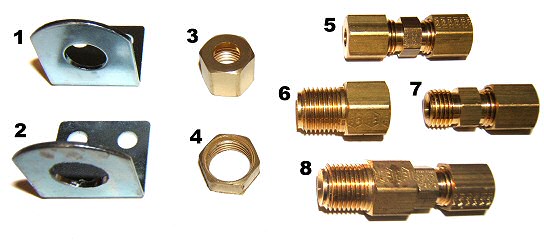

There's more than one way to skin a cat, and you might find bicycle cables and hardware that will work for this job. On subsequent installations, I used a variety of brass tubing and brake fittings, as shown in Figures 5–7.

Figure 5 |

| Figure 5-1: Right-angle bracket from choke cable kit Figure 5-2: Bracket with large hole drilled out to 7/16" Figure 5-3: Compression nut for 1/4" tubing (Watts A-3 PB61) Figure 5-4: Compression nut cut down to act as a lock nut Figure 5-5: 1/8" double compression fitting (Weatherhead 62x3) Figure 5-6: Adapter, 3/16" inverted male by 1/4" inverted male (Weatherhead 7818) Figure 5-7: 1/8" double compression fitting with one compression nut and collar removed Figure 5-8: 1/8" fitting joined to adapter Figure 6: On bracket with sheath, compression collar, and nut Figure 7: Finished barrel stop assembly with cable |

|